1

/

of

1

Michigan Wholesale Tool Supply

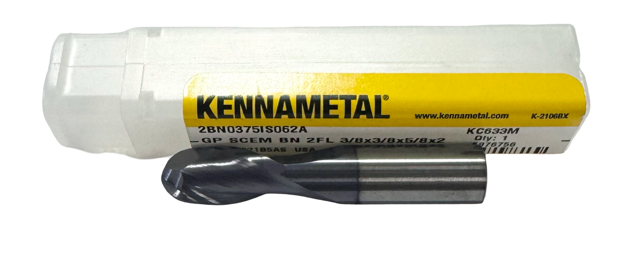

Kennametal 3/8" Carbide Ball End Mill 2 Flute PVD Coated USA Made

Kennametal 3/8" Carbide Ball End Mill 2 Flute PVD Coated USA Made

Regular price

$12.99 USD

Regular price

$0.00 USD

Sale price

$12.99 USD

Unit price

/

per

Shipping calculated at checkout.

Free Shipping:

Available on all orders over $75 in value, shipping to the lower 48 states. Refer to our

Shipping Policy for more details.

Same-Day Shipping & Handling Cut-Off Time: Orders placed before 3:00 PM (EST) Monday through Friday, ship on the same business day.

No Returns Or Exchanges: Being in the wholesale business we offer our products at well below regular prices, for the intent of resale. Therefore, we do not accept returns or exchanges. Refer to our Refunds Policy for more details.

Low stock: 1 left

Couldn't load pickup availability

Kennametal 3/8" Carbide Ball End Mill 2 Flute PVD Coated USA Made

PRODUCT DESCRIPTION

Specifications

| Mill Diameter (Inch) | 3/8 |

| Mill Diameter (Decimal Inch) | 0.3750 |

| Number Of Flutes | 2 |

| End Mill Material | Solid Carbide |

| Length of Cut (Decimal Inch) | 0.6250 |

| Length of Cut (Inch) | 5/8 |

| Shank Diameter (Decimal Inch) | 0.3750 |

| Shank Diameter (Inch) | 3/8 |

| Overall Length (Decimal Inch) | 2.0000 |

| Overall Length (Inch) | 2 |

| Single Or Double End | Single |

| Coating/Finish Family | TiAlN |

| Centercutting | Yes |

| Cutting Direction | Right Hand |

| Flute Direction | Right Hand |

| Extended Reach | No |

| Coolant Through | No |

| Helix Angle | 30 |

| Primary Workpiece Material | Stainless Steel; Cast Iron; Steel |

| Primary Workpiece Material Code | P; K; M |

| Coating/Finish | TiN; TiAlN |

| Variable Helix | No |

| Variable Index | No |

| Chipbreaker | No |

| Flute Type | Spiral |

| Shank Type | Straight-Cylindrical |

| Length Type | Standard |

| Coating Classification | PVD |

| Helix Style | Medium |

| Nose Radius (Decimal Inch) | 0.1875 |

| Neck Length (Decimal Inch) | 0.0000 |

| Reach Length (Decimal Inch) | 0.6250 |

| Mill Diameter Tolerance | +0.0000/-0.0020 in |

| Shank Diameter Tolerance | +0.0000/-0.0035 in |

| Series | GOmill 2BN |

| System Of Measurement | Fractional Inch |

| Additional Information | Solid Carbide End Mill with Excellent Cost-Benefit Ratio. Eccentric Relief Increases Cutting Edge Stability for Long Tool Life & High Surface Quality. Eccentric Relief Eases Regrinding & Reduces Reconditioning Cost. Center Cutting for Plunging & Ramping Operations. |

| Manufacturers Catalog Number | 2BN0375IS062A |

| Material Removal Type | Roughing & Finishing |

| UNSPSC Code | 27112803 |

© Copyright . All rights reserved.

Share